Study and realization of rotary hearth and static gasification reactors for chemical, pharmaceutical and municipal waste. The final set up of the new T.W.R. process based on gasification with absolute hydrogen (H2) and carbon dioxide (CO2) production.

The application of the new system in comparison with the traditional incineration plants can enable to obtain the following 5 great advantages.

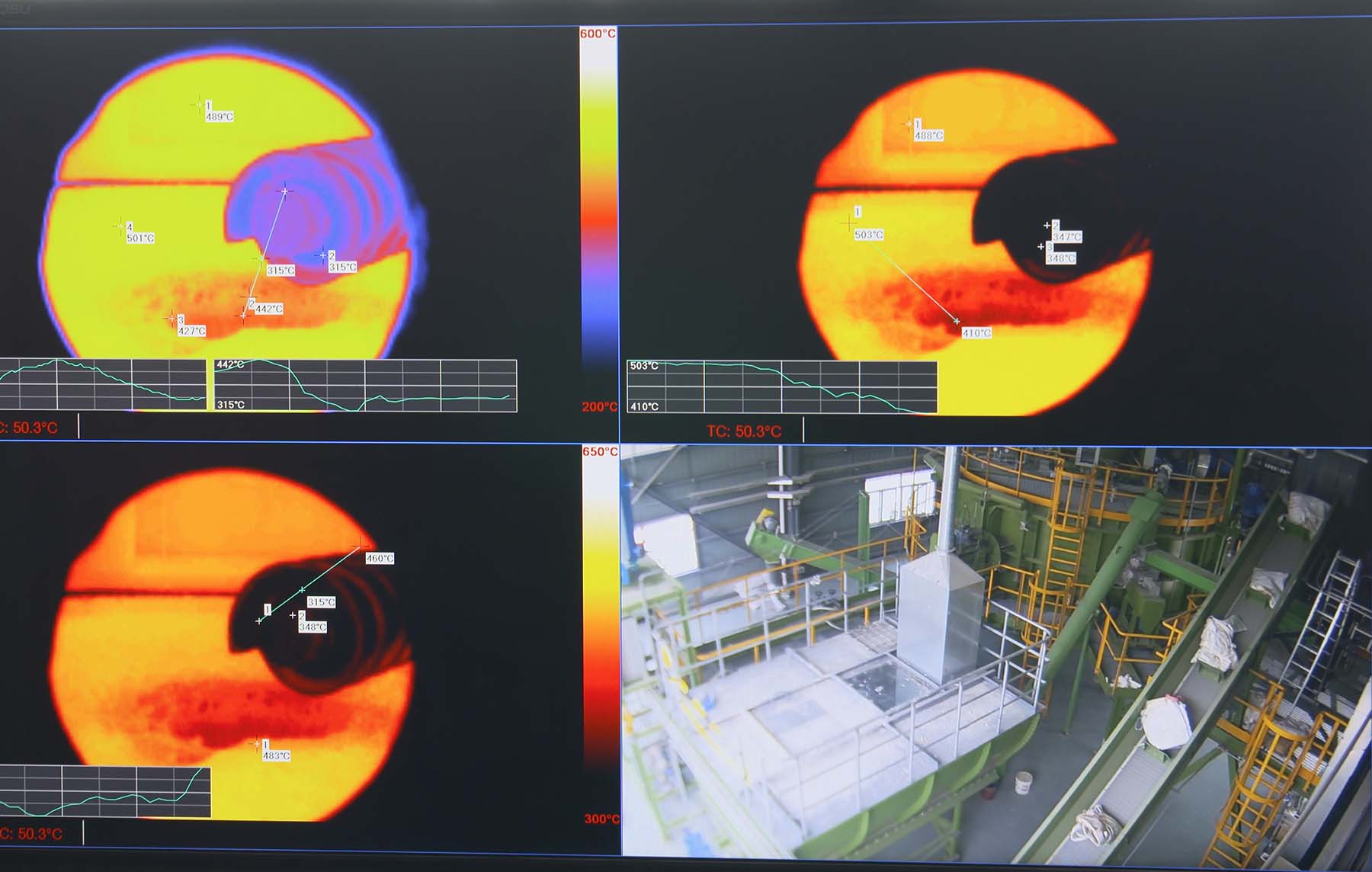

Development and realization, by its own technicians, of EIPICS (Ecologia Informatica Plant Integral Control System) to manage and to monitor thermal oxidation and gasification continuously, allowing a complete management of critical parameters of any industrial process, especially of gasification and incineration plants of raw materials and waste storage system, able to guarantee a very good safety level with competitive costs.